T: 01494 490 480 | E: sales@cta-uk.co.uk

Technical Moulding Services For You

CT Alliance provides injection moulding and contract manufacturing services for the supply of precision plastic components and assemblies to the medical, food and engineering industries.

Engineering-based company led by engineers with a hands-on approach

Established over 45 years as mould makers and precision injection moulders

Turnkey contract manufacturing, from concept to completion

5 all-electric moulding machines, down to 1g shot weight

White rooms and customer-specific manufacturing cells

Services

Product Design

CT Alliance provides development and manufacturing services from product concept, through prototyping, mould making, validation through into high volume production.

Tooling Manufacture

Precision toolmaking is crucial to the efficient production of quality injection moulded components. In-house design and manufacture of injection mould tools ensures that every detail of the component design is precisely reproduced whilst incorporating the specific needs of the selected polymer.

Injection Moulding

Plastic injection moulding of precision components is our core business and one at which we have excelled for over 45 years. Our medically certified, all electric moulding machines deliver unrivalled high tolerance repeatability. Our six axis robots ensure part protection and clean lights out production.

Product Assembly

Our plastic injection moulding facilities are complemented by assembly rooms providing automated and manual completion of products in white rooms that have been designed to progress to class 7 & 8 clean rooms.

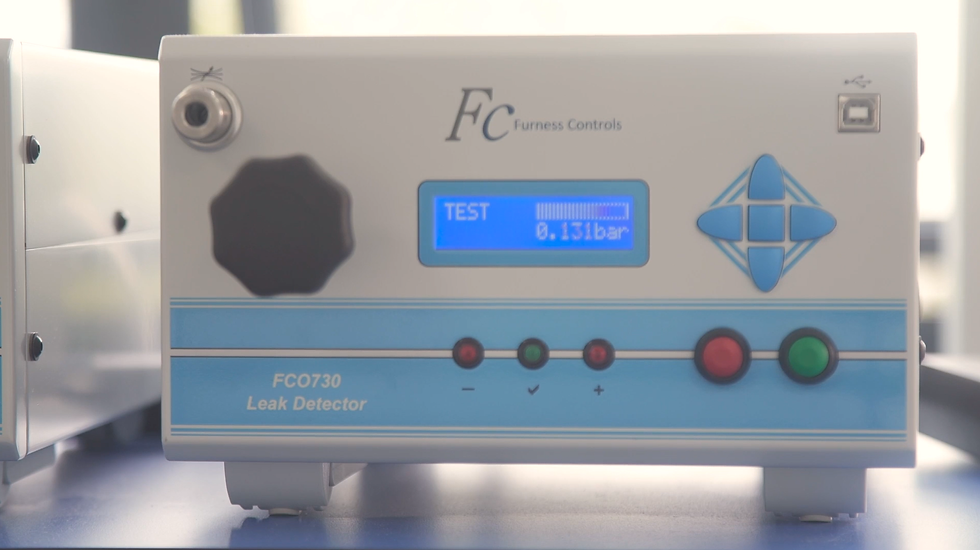

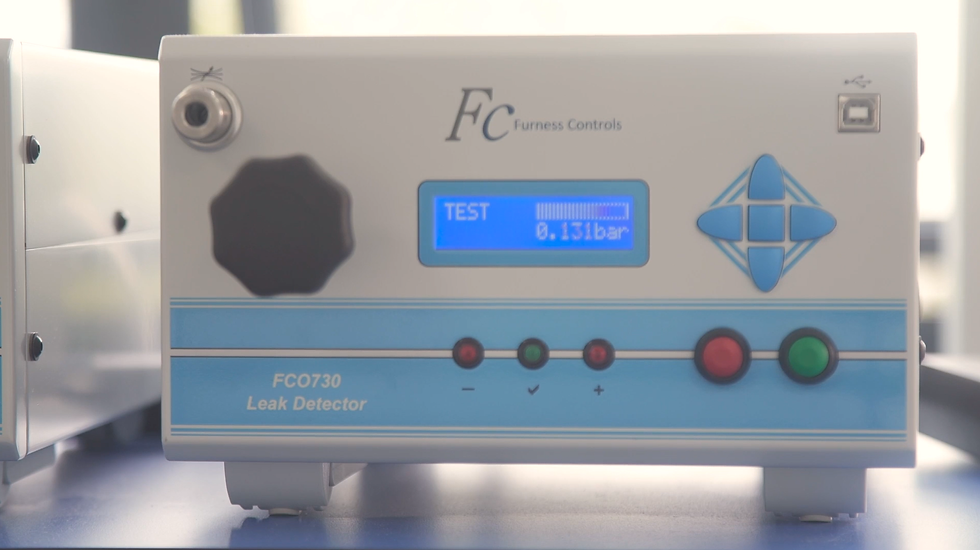

Quality Assurance

Quality assurance is a priority and our quality management system encompasses ISO 9001:2015, supporting everything we do for our customers.

Inspection

CT Alliance can provide both digital and conventional inspection reports. Using 3D laser scanning equipment, we can provide comprehensive 3D data inspections, with full colour plots, feature analyses and more. Detailed conventional reports can also be made using calibrated CMM vision and touch probe machinery.